What is Bird Safe glass?

Bird-safe glass features a wide range of aesthetic options and manufacturing techniques that deliver the following bird-friendly characteristics:

- A surface texture that breaks up continuous reflections, minimizing or eliminating the “mirror” glass effect (see textured glass, channel glass, and etched glass)

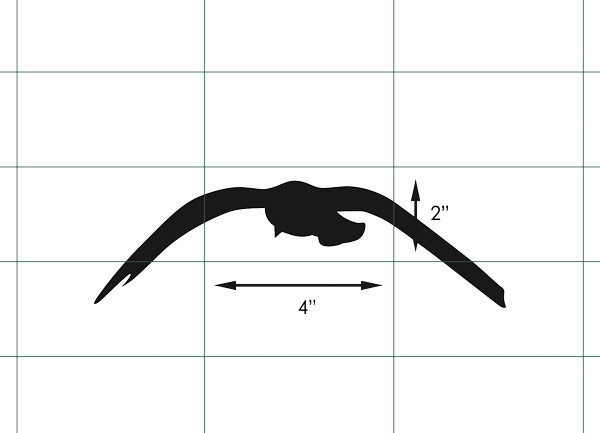

- A bird-safe pattern or design that conforms to the 2″x4″ or Canada’s 2″x2″ rule – more on that below (see fritted glass, etched glass, and digitally printed glass)

- A combination of the two

Image 1: Textured glass facade minimizing continuous reflections, as seen at Silesian Museum. | Image 2: Fritted pattern glass designed to the 2″ x 2″ rule, as seen at Kinnick Stadium. | Image 3: Surface #1 pattern-fritted glass, as seen at the JCCC Fine Arts Building. It simultaneously minimizes reflections and conforms to the 2″ x 2″ bird-safe rule.

Why It’s Important

Accidental collisions with glass in buildings are the second leading cause of bird fatalities in North America. According to the American Bird Conservancy, the death toll reaches over a billion birds a year, threatening our biodiversity and ecosystem. Local and state governments have taken note, and are now enacting legislation to require the use of bird protection glass for new construction and major renovation projects. Thankfully, numerous sustainable and affordable solutions are at the ready in the form of multiple varieties of bird-safe / bird-friendly glass.

Glass Reflectivity and Bird Safety

One of the main reasons birds accidentally collide with architectural glass is because they simply don’t understand reflections. To them, instead of appearing as a solid obstacle, reflective glass facades and windows often appear as an extension of the natural habitat – open skies or sheltering vegetation. A proof that glass reflections are one of the leading causes of bird collisions is that the highest rate of avian fatalities occur in the morning, when building facade reflectivity is at its peak (the sharper the angle of light, the more reflective the glass surface). This also coincides with the time of day when birds are most active.

Avoiding highly reflective, coated architectural glass varieties is the first step towards bird-friendly architecture. To further reduce the risk of bird collisions, architects and designers can specify architectural glass featuring a surface texture that proactively breaks up continuous reflections, signaling to birds that there is an obstacle on their flight path.

Reflection-busting textured channel glass as seen at Carbondale Branch Library, CO.

Bird-Safe Textured Glass / Channel Glass

Bendheim offers a wide variety of clear and ultra-clear (low-iron) textured glass designs that are effective bird-safe solutions.

Our most popular textured glass for exterior applications is the three-dimensional, U-shaped Lamberts® channel glass. It is exceptionally well-suited for facades due to its ability to build expansive glass walls, including curves and glass-to-glass corners, featuring minimal vertical framing. It is available in a range of light-diffusing, reflection minimizing surface textures, as well as a “clear” (Clarissimo™) pattern designed to maximize views.

A mix of Clarissimo and textured glass channels at the new Capital One Bank and Café, Chicago.

Bird-Smart Glass Testing

Curious about the bird-safety performance of our Clarissimo™ channel glass, we tested it with the help of the American Bird Conservancy (ABC) at the Powdermill Nature Reserve in Pennsylvania. The flight tunnel testing determined that even in its clearest form, channel glass presents an effective bird protection. Please see this video for more information on ABC’s testing and Bird-Smart certification for glass:

Among the key benefits of textured / channel glass is the ability to provide occupants the desired level of visual privacy, while enhancing the daylight potential of the building. Textured glass diffuses light, filtering a higher-qualify daylight into the interior that regular clear glass. We are yet to see secondary daylight control devices being used when the building exterior is made of our Lamberts® channel glass.

Another eco-forward benefit of Lamberts channel glass is its low-carbon footprint, thanks to the use or renewable energy and a high percentage of recycled content (as much as 40% post-consumer). Please see our channel glass’ environmental product declaration (EPD) for more information.

Bird-safe textured channel glass rainscreen at New York’s South Street Seaport Pier 17.

Bird-Safe Glass Patterns | The “2×4” / “2×2” Rule

Birds are experts at navigating dense green vegetation, finding small openings through twisted tree branches. They even successfully avoid flying through obstacles as delicate and subtle as spider webs. The principle behind bird-friendly glass patterns is using this sensitivity to make even highly see-through glass “visible” to birds.

The “2×4” bird-safe rule is based on testing, and presents an easy to follow formula to choose an effective bird protection glass solution, or create an effective customized pattern. Essentially, it stipulates that horizontal design elements (i.e. lines or dots) should be spaced no more than 2” from each other. Vertical design elements should be spaced no more than 4” apart. Canada’s stricter standard recommends both horizontal and vertical design elements to be spaced no more than 2” apart.

A variety of Bendheim decorative glass types can be selected in the 2″ x 2″ rule for bird protection applications, including etched glass, decorative laminated glass, digitally printed glass, and pattern frit glass.

This sloped glass rainscreen facade features vertically and horizontally shingled etched glass panels.

Bendheim’s SatinTech® etched glass is a great, time-tested glass solution. Its satin-smooth matte finish is achieved through chemical etching. The process creates microscopic “peaks and valleys” in the surface of the glass, which are so miniature they don’t trap oils and dirt the way sandblasted / particle blasted glass can. Etching can cover the entire glass surface, fully obscuring views and diffusing the light, or can be patterned, where the design is applied through a “printing” screen. Patterns can range in openness, offering various degrees of obscuration. Linear patterns tend to be very popular due to their timeless appeal, but more non-traditional “organic” patterns are a great way to highlight the facade and give it a distinct visual identity.

Our Oberon™ pattern-etched glass is available in sheet sizes reaching 69″ x 126″ (1.8 m x 3.2 m) and 1/2″ (12 mm) thickness.

Decorative laminated glass can be used to insert a variety of exterior-appropriate decorative interlayers, filters, or digital prints into the glass. Prints in particular are becoming an increasingly popular option, thanks to their ability to create photo-realistic mural facades, or to add custom logo elements to the facade. High-resolution digital images or scalable vector graphics are imprinted onto specialized clear filters, and then laminated between two lites of low-iron glass. The near-colorless low-iron glass renders truer colors in comparison with regular glass, which features a distinctive bluish-green tint.

Digitally printed images can also be produced through the “direct-to-glass” printing technique. Special frit-based paints are used to apply the design to the glass, and are then fired onto the glass at high temperatures. The resulting product is safety tempered (heat strengthened).

Right: Bird-friendly linear pattern-fritted glass at Kinnick Stadium, Iowa City, IA is an effective collision deterrent, while becoming nearly invisible at certain angles.

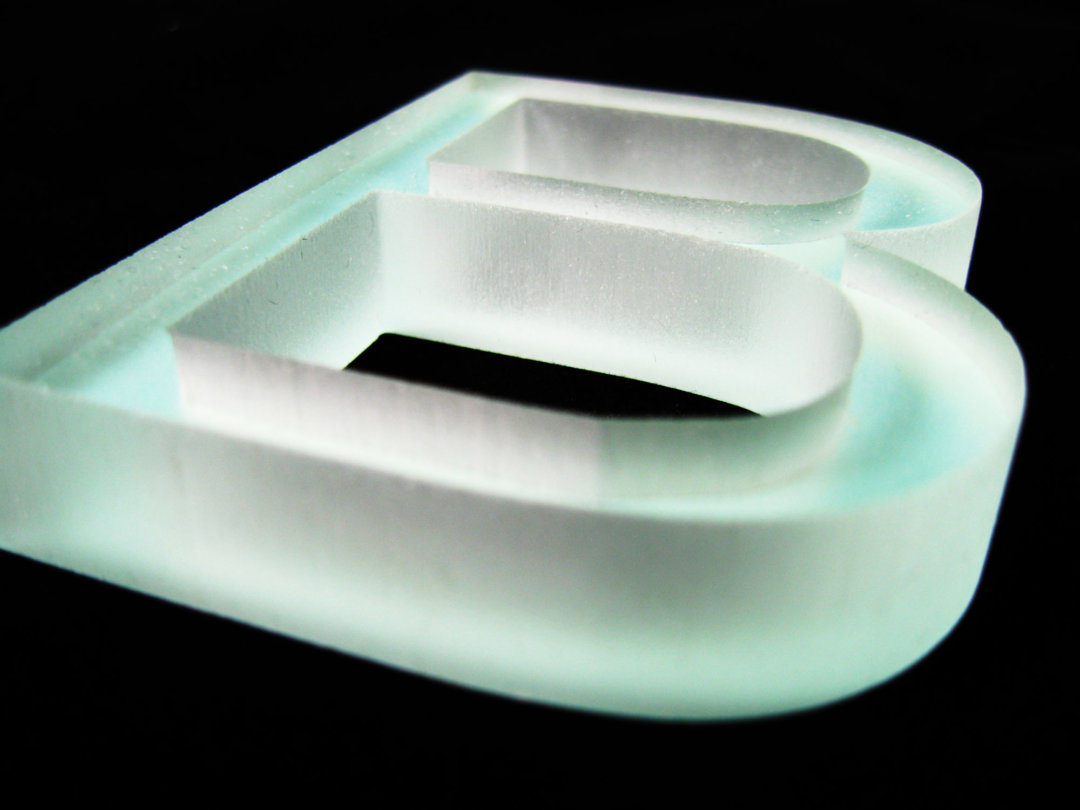

Decorative frit glass is among the most popular options to create customized bird-friendly glass designs for exterior applications, due to its durability, ease of customization, large panel sizes, and cost-effectiveness. Pulverized, powdered glass colors (frits) are applied to the glass surface using a printing screen to create the desired designs. The glass is then heat treated (tempered) to “seal” the frit.

Thanks to their exceptional durability against the elements, frit glass designs can be applied to any of the glass surfaces, including the outermost Surface #1.

Surface #1 Frit Glass: Most Effective Bird-Safe Glass

Bendheim’s Lumi Frit surface #1 glass is an exceptionally effective bird protection option, because it simultaneously incorporates the 2″ x 2″ rule and breaks up continuous reflections by wearing its pattern on the outermost (most reflective) glass surface.

Bird protection is not the only design benefit of this type of glass. In the Johnson Community College example above, our Lumi Frit surface #1 pattern was applied primarily to create an ultra-white glass facade aesthetic in a north-facing location that would normally be cast in the shadow of the building. Rather than appearing dark and downcast, our white fritted low-iron glass creates a brilliant, luminous facade, as daylight reflects off its dot-fritted surface. Fritted glass also provides a solar shading benefit, reducing the solar heat gain and improving the energy efficiency of the glass facade.

White dot Surface #1 frit glass at Johnson County Community College, Overland Park, KS

Effective Bird Protection

Textured, etched, fritted, and digitally printed glass varieties meeting the 2″ x 2″ bird-friendly rule are all proven, effective solutions for avian-safe glass buildings. In addition to helping avoid collisions, these decorative architectural glass varieties present the opportunity to lend a unique aesthetic to the building and enhance its design, privacy, and daylighting potential.

New York City’s Jacob Javits Convention Center, for example, used to be one of the deadliest structures for birds prior to its renovation by FXCollaborative. Bird safe glass featuring a subtle dot frit pattern replaced the offending mirrored glass throughout the facade. The new patterned glass appears transparent, but has been shown to reduce bird collisions by as much as 95%. For more information, see “How Architects Are Designing Buildings With Birds in Mind,” Architectural Digest, https://www.architecturaldigest.com/story/how-architects-designing-buildings-birds-mind.

Ineffective Bird Protection

Bird decals are not effective bird collision deterrents, unless they cover a substantial portion of the glass. At that point, however, the aesthetic disadvantages are obvious. A properly designed fritted glass pattern is a much better choice, offering greater clarity and visibility, while presenting effective bird protection.

What are the standard manufacturing tolerances for specialty architectural glass?

Bendheim’s vertically-integrated production facilities and skilled workers fully fabricate specialty architectural glass to the client’s specification, within the standard glass industry tolerances. In-house processes include: cutting, polishing, carving, back-painting, tempering, and several types of lamination. Learn about our capabilities here: bendheim.com/capabilities.

MANUFACTURING TOLERANCES

Cutting:

- For 1/8” (3 mm) to 1/4” (6 mm) thick glass = +/-1/16” (+/-1.5 mm)

- For 3/8” (10 mm) to 3/4” (19 mm) thick glass = +/-1/8” (+/-3 mm)

- For patterns & shapes of any glass thickness = +/-1/8” (+/-3 mm)

Edgework:

- Minimum thickness = 5/32” (4 mm)

- Minimum piece size = 2.5” x 2.5” (64 mm x 64 mm)

- Minimum Width to Height ratio of the piece = 1 to 10

Hole Drilling & Notching:

- Placement tolerances for 1/8” (3 mm) to 1/4” (6 mm) thick glass = +/-1/16” (+/-1.5 mm)

- Placement tolerances for 3/8” (10 mm) to 3/4” (19 mm) thick glass = +/-1/8” (+/-3 mm)

- Minimum radius for cut-outs and corners = the thickness of the glass

- Minimum diameter of holes for tempered glass only = 1/4” (6 mm) or the thickness of the glass, whichever is greater

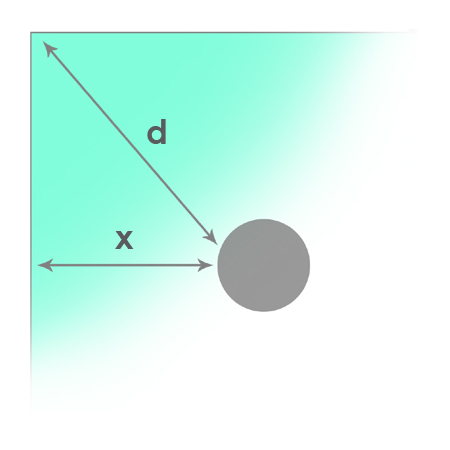

Hole Location for Tempered Glass Only:

Hole location for tempered glass

| Glass Thickness | x-min. | d-min |

| 5/32” (4 mm) | 1/4” (6 mm) | 1 1/16” (27 mm) |

| 3/16” (5 mm) | 5/16” (8 mm) | 1 1/4” (32 mm) |

| 1/4” (6 mm) | 3/8” (10 mm) | 1 5/8” (41 mm) |

| 3/8” (10 mm) | 9/16” (15 mm) | 2 7/16” (37 mm) |

| 1/2” (12 mm) | 3/4” (19 mm) | 3 1/4” (83 mm) |

| 3/4” (19 mm) | 1 1/2” (38 mm) | 6 1/2” (165 mm) |

Tempering:

- Min. thickness = 5/32” (4 mm)

- Max. size for 5/32” (4 mm) thickness = 20 sq. ft.

- Max. size for 3/16” (5 mm) or greater thickness = 69” x 145” (1.75 m x 3.68 m)

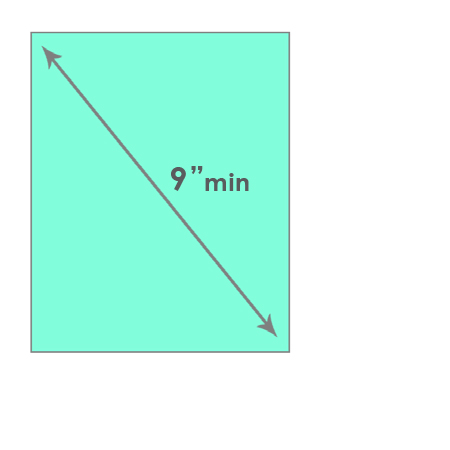

- Min. diagonal dimension = 9” (229 mm)

Lamination:

- Max. size = 72” x 130” (1.83 m x 3.3 m)

- Min. size = 1” x 1” (25 mm x 25 mm)

Fabrication Drawings:

When drawings are required to highlight specific fabrication details, please submit clear and detailed sketches, complete with all required information, i.e., hole & notch location, radius, etc. Every drawing submitted should be labeled with the corresponding Bendheim order number to ensure proper fabrication.

Custom Waterjet-Cut & Engraved Glass:

Please provide the required specialty font(s) and artwork in Windows TrueType format for fonts, vector files for graphics.

Custom Color Back-Painted Glass:

Color matching within 0.05 tolerance

How heavy is glass in relation to its thickness?

Glass is a relatively heavy material. Glazing large openings often requires thicker & heavier glass to minimize deflection and withstand the imposed wind loads. A notable exception is channel glass, which can achieve greater spans in relatively lightweight 1/4″ (6 – 7 mm) thickness thanks to its unique U-shape.

Thicker glass may also provide additional aesthetic advantages, including lending a greater sense of depth and body to the wall. Naturally, the thicker the glass, the greater its weight:

| Glass Thickness | Approx. Weight |

|---|---|

| 1/8” (3 mm) | 1.5 lb/ft² (7.5 kg/m²) |

| 5/32″ (4 mm) | 2 lb/ft² (10 kg/m²) |

| 3/16” (5 mm) | 2.5 lb/ft² (12 kg/m²) |

| 1/4″ (6 mm) | 3 lb/ft² (14.5 kg/m²) |

| 9/32” (7 mm) | 3.5 lb/ft² (17 kg/m²) |

| 5/16″ (8 mm) | 4 lb/ft² (19.5 kg/m²) |

| 3/8″ (10 mm) | 5 lb/ft² (24.5 kg/m²) |

| 1/2″ (12 mm) | 6.5 lb/ft² (32 kg/m²) |

| 3/4″ (19 mm) | 10 lb/ft² (49 kg/m²) |

| 1” (24 mm) | 13 lb/ft² (64 kg/m²) |

What is annealed glass? What is annealing?

Annealing is the controlled cooling of glass during the manufacturing process. It is the first level of architectural glass production. The process prevents residual stress in the glass, allowing it to be easily handled and processed.

Annealed glass is not as strong as tempered or heat-strengthened glass of the same thickness, and breaks into large shards. It is not safety glass.

What is safety glass?

Safety glass is tempered glass (also referred to as “toughened” or “fully tempered” glass) and/or laminated glass that meets the requirements for ANSI Z97.1 and the federal safety standard CPSC 16 CFR Part 1201 (Consumer Product Safety Commission Safety Standard for Architectural Glazing Materials).

Glass is a breakable material. If it breaks into sharp pieces, or shards, it can injure people and pets. Safety glass improves occupant safety and well-being by significantly reducing this risk. In the case of tempered glass, if broken, it exhibits a characteristic “dice” break pattern of many small pieces that minimize the risk of injury. In the case of laminated glass, if broken, it remains in place, held together by the plastic or resin interlayer at its core.

Safety glass is typically identifiable through a permanent marking (a safety seal), generally located in one of the corners of the glass piece. This marking cannot be removed without damaging or breaking the glass.

The US standards for testing and classifying safety glazing materials are:

- ANSI Z97.1 (American National Standards Institute’s Standard for Safety Glazing Materials Used in Buildings)

- CPSC 16CFR, Part 1201 (Consumer Product Safety Commission Safety Standard for Architectural Glazing Materials)

Where should safety glass be used?

The Consumer Products Safety Commission establishes the federal standards and requirements for safety architectural glass. Federal safety glazing law requires the use of safety glass in defined hazardous locations, designated by the Model Building Codes. Generally, these include:

- Bath and shower enclosures

- All doors, including storm doors, sliding doors, and combination doors

- Sidelites, including and any glazing next to a door or an opening for human passage, if the nearest exposed edge is within 24” (0.6 m) of the vertical edge of the door or the bottom exposed edge is less than 60” (1.5 m) above the walking surface

- Areas where the glass is adjacent to walking surfaces and the bottom edge of the glass is within 18” of the floor

- Areas where the top edge of the glass is more than 36” above the floor

- Glazed panels greater than 9 ft.2 (0.8 m2)

Local building code authorities may have additional safety glazing requirements, which can vary by state, county, city, town, or borough. Because each state has either adopted the model federal safety building code, modified it in some sections, or written completely new sections, it is imperative to be guided by the particular state or local building code where the glass is to be installed. For detailed information, please contact your local code officials.

What is laminated glass? Is it safety glass?

Laminated glass is a safety glass that contains two or more glass lites permanently bonded together with one or more PVB, EVA, or liquid resin interlayers. It meets the requirements for ANSI Z97.1 and/or CPSC 16 CFR 1201, and is typically labeled with a “safety” logo identifying the fabricator, glass type, and the standard it meets. Additional benefits of laminated glass can include improved UV and sound control. Various decorative laminates, including virtually unlimited custom color and interlayer options, are available from Bendheim.

What is tempered glass? Is it safety glass?

Tempered glass is also referred to as “toughened” or “fully tempered” glass. It is heat-treated safety glass with a minimum surface compression of 10,000 psi or a minimum edge compression of 9,700 psi. The surface of tempered glass is approximately four times stronger than the surface of regular annealed (non-safety) glass of the same thickness.

When broken, tempered glass shatters into small, relatively harmless pieces. This characteristic “dice” break pattern minimizes the risk of serious injury.

Bendheim tempered glass meets the requirements for ANSI Z97.1 and/or CPSC 16 CFR 1201, and is typically labeled with a “safety” logo identifying the fabricator (Bendheim), glass type, and the standard it meets.

Bendheim’s tempered channel glass is SGCC-certified and has a “safety” logo permanently etched into the glass, in compliance with federal regulations. The Safety Glazing Certification Council (SGCC) is the largest independent third-party that inspects and test tempered glass to confirm the manufacturing process and result. The SGCC is a voluntary organization. Satisfactory participation in the Council allows the glass manufacturer/fabricator to etch the SGCC logo permanently onto the glass, as notification that the glass has been properly produced.

Tempered glass is required as safety glazing in “hazardous” applications, such as floor-to-ceiling partition walls, entrance doors, sidelites, etc.

Glass cannot be further processed (cut, drilled,etc.) after tempering.

If you have a question or concern, please fill out the form below to contact a Bendheim Representative and we will reach back out to you in a timely manner. You may also call us at 800.221.7379 anytime between 9:00 am – 5:00 pm EST (Mon–Fri, except holidays).